Qualification campaigns are generally associated with equipment dedicated to sectors that encounter particularly demanding environments: nuclear, rail, marine, automotive, defense, aeronautics, space. The level of requirement is even higher when the equipment is associated to a security concept. These environmental requirements are often part of the specifications given by a customer to his supplier.

In this context, our engineerings aim to ensure the right adequacy between the constraints to be satisfied and the real requirements resulting from the life profile of a product, but also between the compliance of the design and the technical solutions used to meet these constraints.

The V-cycle representing the development stages of a product and the interactions between the stages of the design phase and the validation phase allows us to better visualize the leverages deployed by our various engineering departments to qualify a material in an optimal manner.

Our engineering services are at your disposal to design and qualify a product while respecting your initial deadlines and opting for the most appropriate design and technology choices. Our engineering services complement our training and testing services.

This support potentially integrates all aspects of the taking into account of the different environments from the design phase to the validation phase: the implementation of the tests themselves, but also the preparation work upstream, the follow-up during the tests and the results analysis downstream.

Depending on your expectations, the project management can be complete or partial:

Our teams are at your disposal to make appropriate recommendations for your needs and expectations.

La gestion de projet est un facteur important pour mettre en place les conditions du succès de votre campagne de qualification

To ensure reproducibility, the tests are standardized with requirement levels based on standardized life profiles.

The test campaigns are therefore generally built around environmental values (electromagnetic or physical) to be applied according to the expected conditions of use. The selected values are generally very high and demanding and sometimes poorly adapted to real needs.

It is increasingly common to encourage writing specifications based on real-world measurements. This customization of tests is done in 3 steps:

Our customized testing services cover electrical and electromagnetic environments as well as climatic and mechanical environments..

The customized testing allows you to:

The approach is based on the simulation of physical phenomena on virtual models (CAD). Applied during the design phase of a material, the calculations make it possible to avoid design errors (under- or over-dimensioning of technical solutions), to validate design choices or even technologies.

Finite element calculations simulate the behavior of a part subjected to the stresses defined in its functional specification. They allow to optimize the architecture of the material during the design phase in order to make it compliant during the qualification phase in a cost/time approach that is extremely efficient compared to a classical methodology of test iterations..

In the context of physical and physicochemical environments, test virtualization concerns vibratory, mechanical and thermal environments.

The main types of calculations for these environments are based on:

Calculations in electromagnetic environments mainly concern the influence of radiofrequency transmitters (radar, communication systems, ...), the visualization of radiated emissions generated by a subsystem, the evaluation of shielding efficiency, the estimation of coupling phenomena (immunity) or the calculation of the current distribution of a direct lightning discharge.

Applied during the design phase of a material, environmental simulation allows to:

It is recommended to consider the test tooling at this stage.

In the implementation of tests in a physical environment (mechanical, climatic and physico-chemical), the test tool is an essential interface between the test means and the specimen to be tested.

In the implementation of tests in a physical environment (mechanical, climatic and physico-chemical), the test tool is an essential interface between the test means and the specimen to be tested.

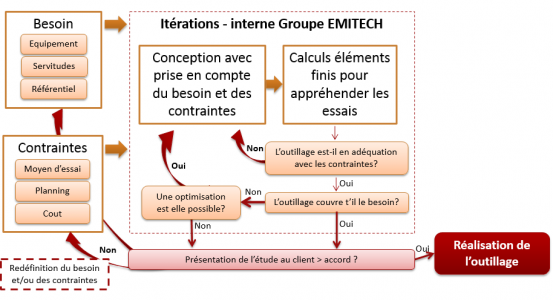

The test tools are designed and manufactured by our engineering offices. They must allow the equipment to be adapted to the means to be used without interfering with the constraints to be applied.

Depending on your needs in terms of frequencies, on-board mass, dimensions..., we optimize the design of the test tooling with the help of numerical simulation and we have a range of adapted materials (steel, aluminum, magnesium) and heat treatment.

The design of an adapted tooling is a challenge for two reasons:

Writing a QTP includes:

La rédaction d'un QTP vous permet :

L'approche est identique à la mise en oeuvre de calculs numériques lors de la phase de conception d'un matériel.

Il s'agit à ce stade :

La virtualisation des essais utilisée en phase d'évaluation permet :

Utilisées comme outil au service de nos études et ingénieries, nos simulations numériques s'exécutent sur des stations de calculs allant jusqu'à 7 Tflops

Elles sont mises en oeuvre dans une approche pragmatique fondée sur le retour d'expérience au sein de nos laboratoires.

les outils à votre disposition sont les suivants :

Nos simulations font notamment appel à :

Calcul en fréquentiel

Calcul en temporel

Nos simulations font notamment appel à :

Emitech Group - Legal information