Launched in 1998, the maintenance department provides its customers in France and Europe with corrective and preventive maintenance of vibration test equipment (electrodynamic and hydraulic) and test benches manufactured by us. Agreements have been put in place to intervene on all major brands of equipment.

In particular, for LDS vibrators, Environne' Tech technicians work according to LDS procedures and with original LDS spare parts.

Maintenance is usually conducted once a year, but a special schedule can be adapted according to the intensity of use (semi-annual, annual, every two years or more) and we also offer a service of intervention on breakdown within 48 hours.

A calibration of your measurement means is proposed in the maintenance contracts: sensors, conditioners, vibration generator.

A dedicated service technician is your single point of contact for all services

All of these services ensure that your test facilities function optimally, with minimal downtime.

|

|

|

Preventive maintenance

Maintain the characteristics and performance

of your test equipment

Technical specifications

Maintain the properties and

performance of your testing equipment

Maintenance tailored to your level of usage. The frequency and duration of our maintenance operations are scheduled in advance, and we guarantee the availability rate of your equipment. We draw up a maintenance register and provide an inspection certificate complying with ISO standard 17025.

Thrusters, hydraulic and electrodynamic excitators, shock machines etc.

We bring you a complete service at a controlled cost!

Our strengths

Specialist services

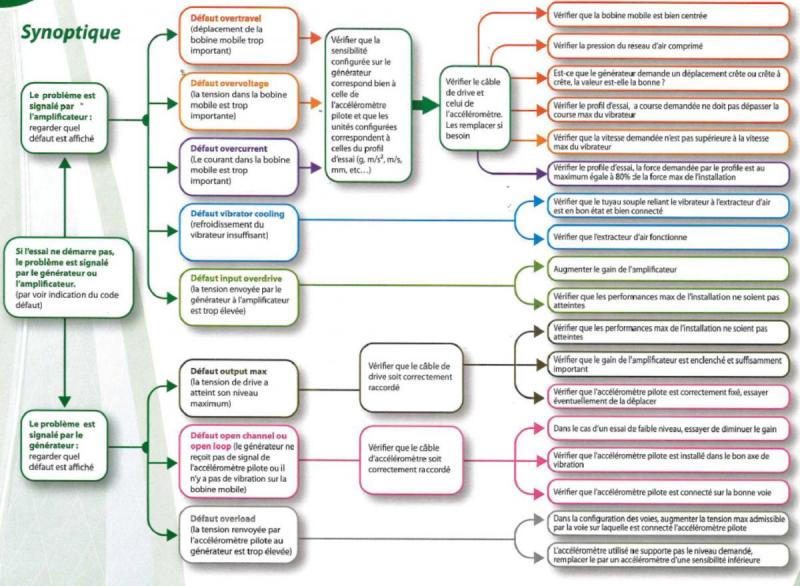

Breakdown diagnoses

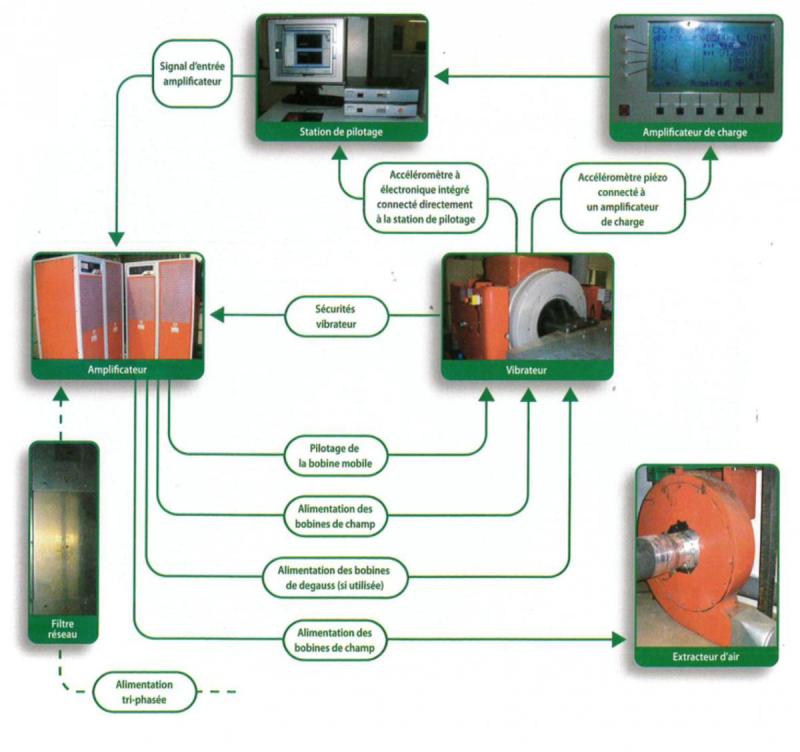

Installation of vibration systems

The Emitech Group announces the creation of an Innovation Department, dedicated to researching and implementing innovative solutions to prepare the future of testing.

Emitech Group - Legal information