Between the initial phase of launching a project for new equipment and the start of mass production, tests are usually carried out in the last straight line at a time when pre-series equipment representative of the design and component choices have been designed.

For the success of these tests, and ultimately so that production is not delayed or made more expensive, it is essential that the nature of these tests, their consequences in terms of design or choice of components and the taking into account of evolution have been considered.

For equipment intended to be placed on the market and subject to approval procedures (CE marking for the European Union, access to certification marks, etc.), knowledge of the procedures and standards in force is also essential to avoid compromising the success of marketing.

We offer analysis, expertise and engineering services designed to help you upstream and downstream of the test campaigns conducted by our laboratories.

More fully prepared on the tests you have to perform, these become a simple formality.

Our know-how in testing, standards and procedures has naturally translated into training services and a wide range of engineering, engineering and expertise.

That includes detailed support on regulatory matters, making sure that you are aware of the testing requirements early on in the product development phase, including updates on regulatory changes.

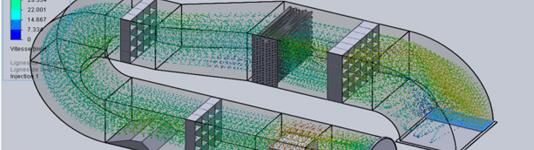

We also offer analyses, engineering operations and simulations which complement our testing services (project management, customised tests, validation calculations, testing tools, QTP, virtual testing and more).

The experience acquired in our laboratories also allows us to propose another kind of engineering that capitalizes on our know-how to design specific test benches.

The Emitech Group announces the creation of an Innovation Department, dedicated to researching and implementing innovative solutions to prepare the future of testing.

Emitech Group - Legal information